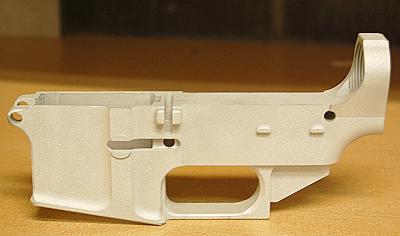

EFormance Engineering AR-15 80% billet lower receiver

WE HAVE DISCONTINUED PRODUCTION, THEY ARE NOT AVAILABLE. THIS PAGE IS HERE FOR INFORMATIONAL PURPOSES ONLY.

|

Introducing the EFormance Engineering billet 80% AR-15 compatible lower receiver.

What you see below is a product nearly a year in the making. Our 80% lower is machined from 7075-T6

billet aluminum, available in a blasted or as-machined finish. Our design tries to mimic the original

AR-15 curves and adheres closely to the print dimensions. You can see the number of similarities and differences

in the pictures below. We tried to keep cosmetic features as close to the original and modified the design

where we thought we could improve it.

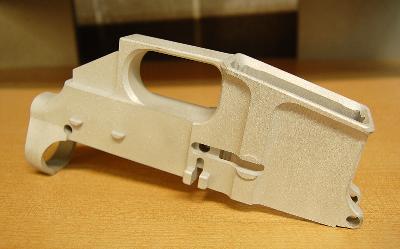

Our design has an enlarged integral trigger guard, to give increased room without the more unconventional "winter glove" style. The result is a trigger guard that should fit the largest ungloved fingers and will permit most gloved fingers to fit comfortably. The guard features a generous chamfer near the grip which blends into the bottom of the FCG, this helps operators with shorter fingers to reach the trigger easier.

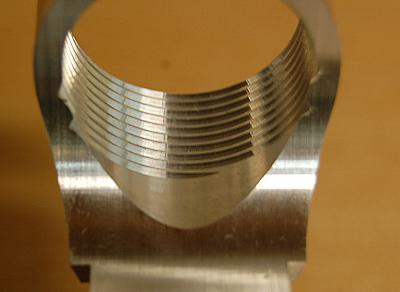

The buffer tower thread is milled in the CNC to give a MIL-spec dimensioned thread that indexes the same for each receiver. You do not need a tap to complete this part.

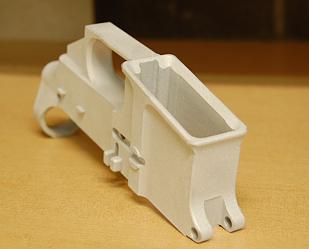

Our magazine wells are wire EDMed. Wire EDM actually takes longer and is more expensive than the milling and/or broaching process, however because wire EDM machines are designed for lights-out machining, it allows us to machine a higher volume of parts. Wire EDM also produces a textured surface which resembles a blasted finish inside the receiver.

The front and rear takedown holes are machined precisely to fit MIL-spec upper receivers, but before you can fit an upper, the Fire Control Group pocket must be machined out. This can be done in a number of ways. If you have access to a mill-drill, benchtop milling machine, or Bridgeport style milling machine, you can readily complete a receiver in around 2 hours, with moderate skill.

We will soon be offering a jig for helping locate the missing holes and guide you in machining the FCG pocket. The jig is being designed to fit our 80% lower directly and locks in place with the rear takedown hole and 2 roll pins. You simply need to clamp the receiver and jig in a milling vise or drill press vise to successfully complete a receiver. You can use any of the existing drilling and clamping jigs already available to complete our receiver design. All of the holes and features are compatible with existing jigs. If you have any questions that aren't answered on this page, please use our feedback form at the bottom of the page to contact us. Features which are complete on our 80% lower receiver:

We have tried hard to make an 80% receiver that looks nice and has all of the heavy lifting done, while leaving the end user to complete the unit and learn their tools in the process. The tools required to complete our 80% lower are not expensive and should be readily available locally or from your favorite catalog supplier. For notes and information on completing your 80% receiver, go to our AR-15 80% lower build page

|